The metallic materials used in Atex devices according to IEC/EN 60079-0 standard

Metallic materials are not subject to the typical problems of plastic materials such as aging and resistance to UV rays, but rather can become ignition sources themselves. This is why the legislation pays particular attention to the parts that act as housing.

by Andrea Battauz, R&D Manager of Cortem Group

Premise

Devices suitable for use in potentially explosive atmospheres are identified according to their type of protection, for example we refer to 'Ex db' explosion-proof enclosures or 'Ex eb' increased safety motors. However, there are a series of general requirements that all devices must comply with, and which are described in IEC/EN 60079-0 standard which enters the details of the materials used. In this context, it must be remembered that metallic materials are not subject to the typical problems of plastic materials such as aging and resistance to UV rays, but rather can become ignition sources themselves. This is why the legislation pays particular attention to the parts that act as housing.

Risk of ignition due to impacts or friction

In electrical devices suitable for use in areas classified as at risk of the presence of potentially explosive atmospheres, the cases are often made of metal, an example of which are the bodies and lids of explosion-proof and increased safety boxes.

An aspect that is typical of equipment intended for use in classified areas is the limitation of the risk of ignition due to impacts or friction.

This phenomenon can be described like this: when two solid surfaces come into contact, at certain forces and speeds, they can emit particles with a higher temperature. Depending on the combination of materials, this excess temperature can reach values of 1000°C and the particles released become incandescent, giving rise to what we call sparks.

Anyone who has worked with a grinder knows how spectacular this phenomenon is, but it can also occur in less conspicuous situations. The impact between a tool and a metal can generate a spark, as can a metal tool falling on a metal structure. Obviously, this situation in common industrial applications does not give rise to concerns but, in areas classified as at risk of the presence of potentially explosive atmospheres, it is considered a possible source of ignition of an explosion. The incandescent particles react with the oxygen contained in the atmosphere, more easily igniting gas mixtures rich in oxidizer.

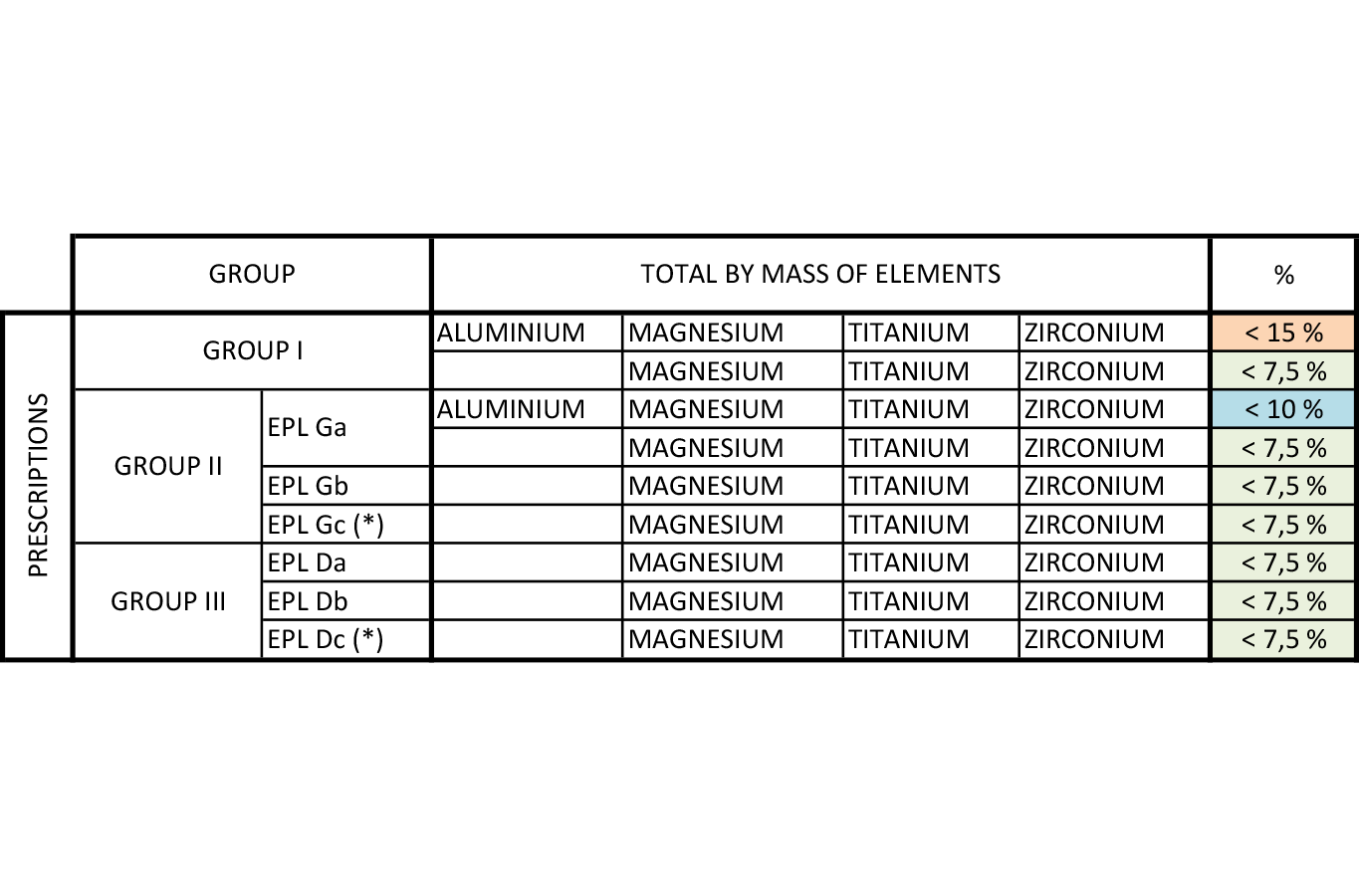

To avoid this phenomenon from occurring, the legislation places limitations on the use of metals that contain alloy elements having a great affinity with oxygen: aluminium, magnesium, titanium and zirconium. Please refer to Table 1 to check the maximum alloy percentages expected for these chemical elements. Asterisk (*) indicates validity only for: fan impellers, protective hoods and ventilation opening protections. [1]

Note that, in contexts where the mechanical risk is higher (such as for Group I mining equipment) or where the probability of the presence of an explosive atmosphere is higher (Group II with EPL Ga), the imposition becomes more severe and also excludes aluminum and consequently all its alloys.

Copper alloys in the presence of acetylene

With the latest edition of the IEC 60079-0:2017 standard, attention was paid to the use of copper alloys in atmospheres with the presence of acetylene.

Copper alloys in the presence of acetylene can show the formation of acetylides on the external surfaces. These compounds easily create sparks if surfaces are abraded or impacted.

Therefore, for the external cases of devices and components made of copper alloy, a limitation of 65% copper content in the alloy or, alternatively, a coating with nickel or tin is required. [2]

Conclusions

EN/IEC 60079-0, the general requirements standard, places limitations on the use of metals, which is why group I mining equipment cannot be made of aluminum alloy and on the market, we can find them in carbon steel, stainless steel or cast iron.

In other cases, the motivation that drives the use of a material is not to be found in the legislation but rather in mechanical technology. Over the years, the technological solution that has made it possible to reduce the cost of a product while maintaining its most significant properties has always prevailed.

Reference standards and bibliography

[1] 8.1 ... 8.4 IEC 60079-0:2017, note that there is the possibility of having alloys that do not comply with the percentages in Table 1, but such equipment must display the “X” symbol in its certificate. For further information, refer to the standard.

[2] 8.5 IEC 60079-0: 2017