Explosion-protection in cereals storage areas

During the summer, the farms are reaping the crops and the products of a year's work of nature are storage in the granaries. The...

During the summer, the farms are reaping the crops and the products of a year's work of nature are storage in the granaries.

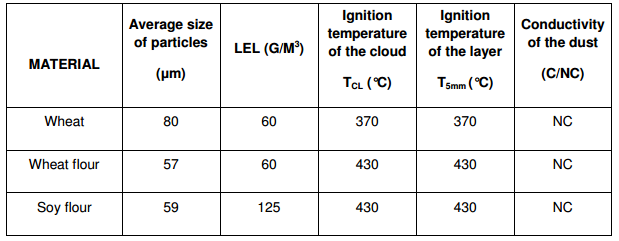

The increasingly large size of the warehouses and the mechanization of the collection, handling and storage of wheat and its derivatives, have led us to consider the dangers of explosion of dust clouds that can occur in the presence of sparks or electrical arcs. We regard as the silos for the storage of cereals (corn, wheat, rice, soybeans, flour, etc..) in which loading, unloading and other processes can generate explosive atmospheres.

Dangerous materials

Area classification

Due to their low specific weight, cereals dusts may remain suspended in the air for long periods generating explosive atmospheres. The relevant standard for the areas classification is the EN 60079-10-2.

Following the standard prescriptions, in grain storage areas, for example, you can have the following classifications Area:

- Internal volume of the silo - Zone 20

- Loading and unloading areas (feeders and hoppers) and adjacent areas - Zone 21

- Volume around the area 21 with an extension of a few meters - Zone 22

- Places where dust can be deposited in layers - Zone 22

- Deposits of packages subject to breakage - Zone 22

Relevant Standards

As per all the equipment installed in hazardous areas, ATEX 94/9/EC and ATEX 99/92/EC standards are the reference point for equipment and protective systems.

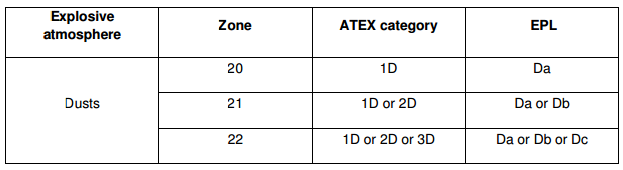

Equipment to be used

All electrical devices are classified into zones which must meet the safety requirements and have the protection degree suitable for the type of classified area, as required by the ATEX directive 94/9/EC. This directive defines the categories 1, 2, 3 (Group II) based on the protection level. EN/IEC 60079-0 (Ed.5) standard introduced the concept of EPL (Equipment protection level). Therefore, following the dictates of the Directive and of the EN 60079-0 standard, we’ve to choose equipment that meet the following requirements: