September, vintage time

September has come It's vintage time, the crops have been harvested in recent months and the barns and silos are now full of wheat and...

September has come It's vintage time, the crops have been harvested in recent months and the barns and silos are now full of wheat and flour. Man has always lived with food powders, but only in the recent few years has understood what is the danger of an incorrect treatment in the handling and storage of these products. The devastating explosions, which periodically occur in rooms where large quantities of combustible dusts are stocked, have attracted attention and both the causes and the means to avoid them were subject of important studies.

It’s not a modern phenomenon; in more than 200 years can be reported "explosions of dust”. The first recognized and recorded explosion of dust occurred in a flour warehouse in Turin in 1785. At that time, the windmills used since the mid-14th century for grinding cereals were gradually replaced by steam turbines, more efficient but also more dangerous. Another great explosion, occurred in Germany in 1887 in the New Mills of Weser Hameln, caused the death of thirty people and injured a large number.

The current situation

Explosions of industrial dust that cause widespread damages are exceptional phenomena (Metz, March 1982, in silos for the storage of barley and malt; Boiry Ste-Rictrude in 1982, in silos for the storage of granulated sugar), but less devastating explosions are more frequent. At this time, according to some statistics about France and Germany, nations that manage carefully these phenomena, an explosion of dust per day occurs, on average, in each of the two countries. The important mechanization of these industries plays, certainly, an important role in this phenomenon. In agri-food industry, the storage capacity, the extension of automation and the number of products in form of powder, with small granulometry, have increased in the recent decades. The phenomenon is, therefore, of enormous interest to anyone involved in systems installed in areas with danger of explosion.

Statistics

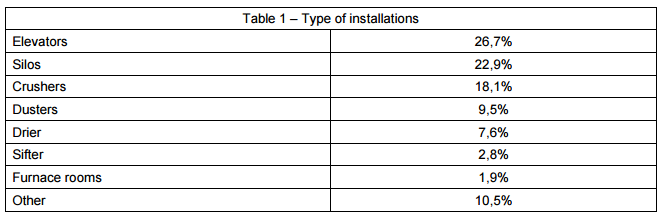

Table 1 shows, for 400 explosions recorded, the types of plants affected in the food industry and fodder for cattle industry.

The question that arises is why, how and with what types of dust product an explosion can occur. In the agri-food and fodder for cattle industries, all organic products are made of carbon, hydrogen, nitrogen, sulfur, oxygen, etc… Therefore, they are combustible elements and, consequently, can cause fires and explosions.

Why and how to determine an explosion

Only recently has been discovered that the food powders could explode alone. Once, it was thought that the powder exploded because of the presence of alcohols or gases resulting from their fermentation. We now know that dusts, depending on their granulometry, behave and follow the same principles as for gases and vapors.

An explosion can occur under three conditions:

- the presence of a carburant gas, usually the oxygen in the air;

- the presence of a combustible product, in this case the dust in suspension;

- the presence of an ignition source.

You will have already recognized the famous "triangle of fire" which shows that the explosion is only a special event of combustion, which is a combustion of extreme speed. However, regarding dusts, in order to describe combustion as an explosion, three additional conditions are required:

- the presence of airborne dust;

- a defined field of concentration;

- a sufficient confinement, otherwise you get a phenomenon of flame (quick combustion with flame, but without a significant effect of pressure).

In order to trigger an explosion, the ignition source has to increase, at least locally, the temperature of the dust cloud so that the oxidation reaction of combustion occurs at a sufficient speed. In case of an electric ignition, the source may be a flashing spark, an arc, phenomena of static electricity or a heated surface. There are a number of European standards for determining the characteristics of clouds of dust explosions.

These are the following four:

- EN 14034-1:2004 – Determination of maximum explosion pressure

- EN 14034-2:2006 – Determination of the maximum speed of pressure increase

- EN 14034-3:2006 – Determination of the lower explosion limit LEL

- EN 14034-4:2004 – Determination of limit oxygen concentration LOC

In the next newsletter, we will see the characteristics of potentially explosive atmospheres for the presence of combustible dust and the methods used to prevent explosions.