Direct and indirect entrances into explosion-proof electrical systems

The systems are mainly divided into systems with metal protective conduits and cable systems. The various devices require cable entries suitable for the type of protection used. The type of cable entry may appear to be a mere theoretical argument, but it has a decisive impact on the safety level of the system.

by Andrea Battauz, R&D Project Engineer of Cortem Group

Premise

As is well known, the systems are mainly divided into systems with metal protective conduits and cable systems.

The various devices require cable entries suitable for the type of protection used.

Specifically, now we analyze the type of protection [0] 'Ex d', at most in its composition with the type of protection 'Ex e'. This is limited to explosive atmospheres due to gas and leaving out the 'Ex n' and 'Ex i' methods of protection in this article.

Generally cables enter devices in three ways:

- directly via conduit sealing fittings

- directly through 'Ex d' cable glands, following the selection criteria as per plant engineering standard EN 60079-14 [1]

- indirectly through the interposition of an increased safety case used as a terminal box.

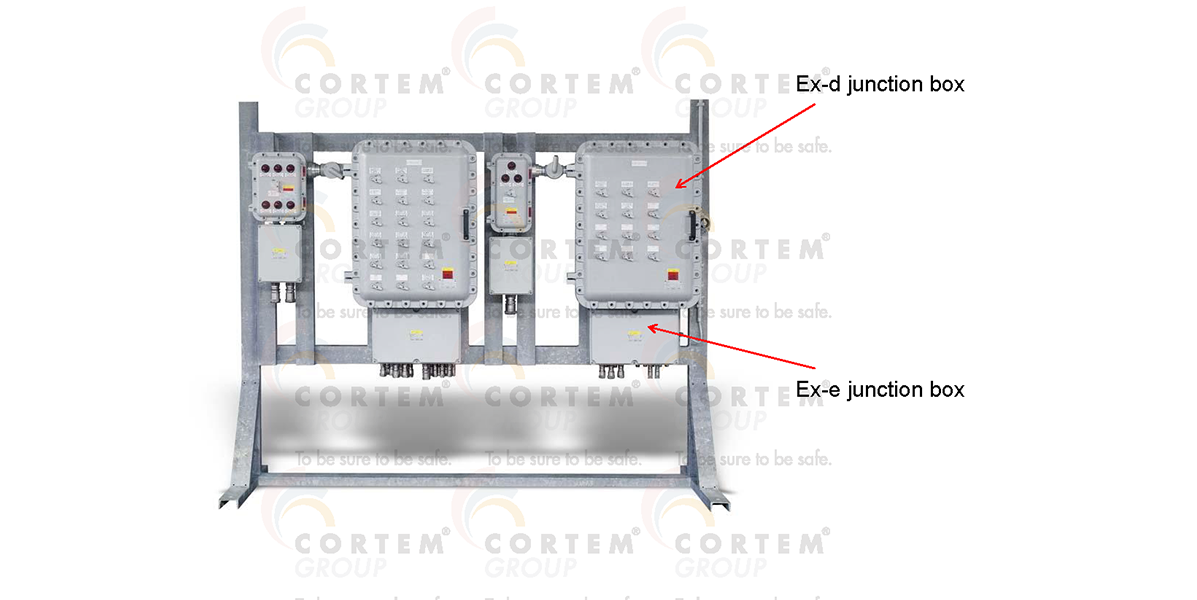

The figure 1 well represents the types of entrance in explosion-proof enclosures and the types of systems.

The direct entries

The entry through sealing fittings is typical of a system with cables in protective metal conduits (conduit) and, therefore, it is the most traditional system in the areas classified as Zone 1. The conductors passing through the metal pipes are sealed in the sealing fitting and then enter the explosion-proof enclosure.

The entry through the 'Ex d' cable gland is the entry solution made entirely in the 'Ex d' protection system which is most often present in the cable system. Logically, the choice of use between a cable gland with barrier and one with a sealing ring is made in accordance with the selection criteria for cable glands according to the EN-60079-14 plant engineering standard [1].

Figure 2: skid with direct cable entries into the lower enclosures by means of sealing fittings

The indirect entries

The third system relates to the connection to the network of those equipment or enclosures that are equipped with an increased safety terminal box. This allows the connection to be made with an 'Ex e' cable gland, that is a certified cable gland equipped with a sealing ring, thus avoiding any on-site sealing operations. Furthermore, since these are 'Ex e' cable glands, it is not necessary to apply the criterion of choice as on 'Ex d' cable glands, which, as far as we talk about it, remains undoubtedly a complex technical evaluation.

With this option, the connection of the explosion-proof device becomes as quick to install as an industrial device.

Figure 3: skid made with indirect cable entries in the lower part

The indirect entries in 'ex d' equipment

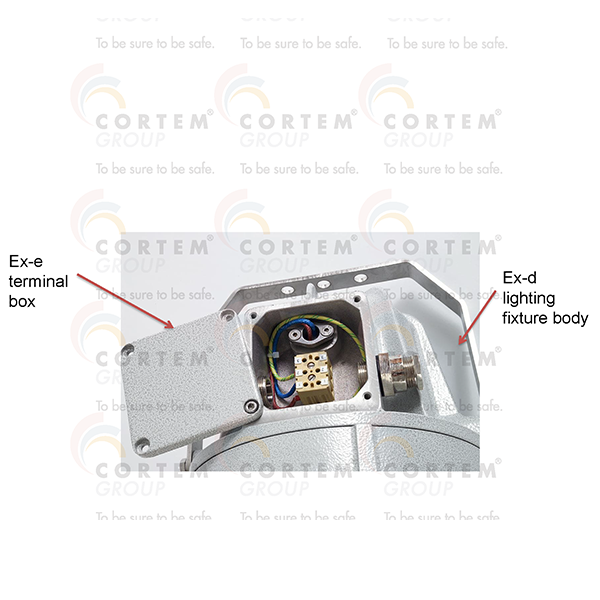

It is interesting to note that more and more 'Ex d' explosion-proof devices use an increased safety terminal box for connection to the system [2].

In these devices, the explosion-proof part is separated from the 'Ex e' terminal box by means of special certified wall passages [3].

This in fact makes these devices very versatile, excluding the on-site sealing procedures required with the use of sealing fittings or barrier cable glands.

Conclusioni

La tipologia di ingresso cavo può apparire un mero argomento teorico, ma impatta in maniera decisa sul livello di sicurezza dell’impianto.

Da non trascurare poi il discorso economico, considerato che il raccordo di bloccaggio e il pressacavo ‘Ex d’ barriera presentano come costo nascosto la loro installazione, ben poco agevole. Per contro, il pressacavo ‘Ex d’ con gommino è di semplice installazione, ma permane la complessità tecnica nel criterio che ne permette l’installazione.

Ecco che quindi possiamo comprendere il valore aggiunto di un’apparecchiatura dotata di scatola morsetti di collegamento realizzata a sicurezza aumentata.

Note, norme di riferimento e bibliografia

[0]Nel prosieguo per semplicità indicheremo il modo di protezione Ex-db come Ex-d e il modo di protezione Ex-eb come Ex-e

[1]paragrafo 10.6.2 della EN 60079-14

[2]troviamo la scatola di connessione a sicurezza aumentata su motori, armature illuminanti e sensori

[3]passaggi sigillati/isolatori passanti/pressacavi interni