Explosion-proof electrical plant: conduit installation

The use of cables for electrical equipment connection in potentially explosive atmospheres is now a common practice. Some time ago,...

The use of cables for electrical equipment connection in potentially explosive atmospheres is now a common practice. Some time ago, explosion-proof materials were connected to each other through steel pipes. Furthermore, the entries into junction boxes presented locking joints which did not allow to a possible explosion to spread through the pipe. The main advantage of this system is that cables are not integrated in rigid tubes, but they go through tunnels like normal cables for industrial plants. Cable entry into explosion proof enclosures is made thanks to the use of special cable glands, which allow both the cable entry directly (British system), either through increased safety enclosures (German system).

These two types of entries are described in detail below.

CABLE INSTALLATION WITH DIRECT ENTRY

In this system, a cable enters directly into the explosion-proof enclosure through an exproof cable gland that prevents to a possible explosion from spreading outside the enclosure.

These cable glands can be of two types:

- barrier cable glands

- glands with elastomeric ring.

Barrier cable glands

Barrier cable glands have a system that allows the wire sealing before it enters into the box. This method ensures any flame propagation outside the enclosure.

In this case, the cable conductors are sealed in a sleeve using a resin which, when inserted in a cable gland, form a rolled joint with the inside part of the body.

Glands with elastomeric ring

In cable glands with elastomer, the cable is wrapped in a gasket that is compressed by a conical system that guarantees that the flame doesn’t spread through the cable gland.

Each cable gland must be in compliance with the security prescriptions of EN 60079-1 standard and the length of the seal or the gasket must ensure the explosion seal.

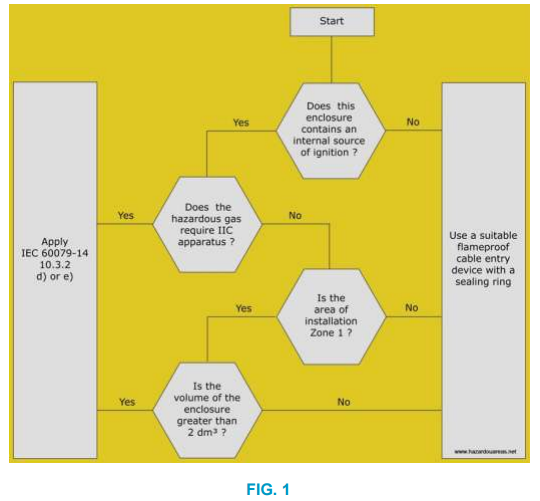

In EN 60079-14-1 standard exists a chart (see Figure 1) that defines when you can use a cable gland with elastomeric seal or when it’s necessary to use a barrier cable glands.

CABLE INSTALLATION WITH INDIRECT ENTRY

This system is used mainly in countries influenced by German technology. It provides an increased safety enclosure with suitable terminals in which cables enter and come out through “Ex e” cable glands. This increased safety enclosure, in order to avoid the transmission of the flame, is connected to an explosion-proof enclosure, which contains electrical equipment that could spark and cause an explosion, through sealed bushings.

“Ex d” Cable Glands

Cable glands which follow the type of protection “Ex d” must comply with of EN 60079-1 standard requirements and must be certified and marked.

In addition to barrier cable glands and elastomeric cable glands described above, “Ex d” cable glands are generally divided into two main categories:

- cable glands for armored cable

- cable glands for normal cable.

Cable glands for armored cable with elastomer have two gaskets: the first is in the front and it’s sealed on the inside diameter of the cable and provides the explosion protection. The second, in the back, protects against the ingress of fluids into the cable gland where the fixture is blocked by two conical rings that ensure the ground connection.

Furthermore, barrier cable glands for armored cable have, in addition to the bushing where the conductors are sealed, an elastomeric gasket in the back that protects against the ingress of fluids into the cable gland where the fixture is blocked by two conical rings that ensure the ground connection.

Cable glands for armored cables are used for the direct entry of non-armored cables in flameproof enclosure. Sealing is done thanks to a gasket directly on the external cable sheath, or, in the case of a “barrier” cable by sealing wires.

There are also "barrier" cables. In this case, the cable is sealed with a resin in a sleeve which, when inserted in the cable gland, form a rolled joint with the inside part of the body.

The use of different types of cable glands, as already indicated above, following the standard EN 60079-14-1. In fact, depending on the type of facility and the junction boxes volume you can use barrier cable glands or simple cable glands with gaskets.