Prevention of explosions caused by dust accumulation on explosion-proof electrical equipment

1. Introduction The engineering companies operating in the petroleum, petrochemical, pharmaceutical, food sectors and also in all those...

1. Introduction

The engineering companies operating in the petroleum, petrochemical, pharmaceutical, food sectors and also in all those areas where the maximum attention must be paid both to the dimensioning and to the maintenance problems of the plants, correctly select the types of equipment to be integrated into the production cycle and produce the documentation that, made available to the end user, provides precise indications on the management and the maintenance methods of these plants.

However, it often happens that the management of the plants is lacking in terms of preventive maintenance, an activity that is vitally important for the compliance with the constructive guarantees of all those electrical equipment installed respecting certain dimensional parameters such as: the belonging to a specific classification of the area in which they must be installed, the correspondence to the temperature class and to the ambient temperature to which they must work correctly without functional interruption.

2. The importance of the maintenance operations

Maintenance, which must be carried out daily to all the equipment, is one of the many activities necessary to comply with the regulatory requirements and for the safety of a correct operation.

Few people know that a device is designed and built taking into account specific regulatory and construction requirements, necessary for the safe operation.

The construction is defined on the basis of a series of tests that are carried out by a third certifying body, which has the obligation to verify that the equipment meets all the standards requirements, such as for example:

- The Verification of the aging of all non-ferrous materials, with aging cycles in a climatic chamber in accordance with the standard.

- The search for the reference pressure, by internal explosion with type and quantity of gas mixture relative to the group to which it belongs, pressure necessary to determine the static test pressure on all products.

- The verification of the maximum allowable dissipation in accordance with the temperature class with reference to the ambient operating temperature.

- The verification of the internal provisions and the minimum isolation distances to be respected, in particular, in the presence of intrinsically safe components with those not intrinsically safe.

- The control of the maximum surface temperature based on the temperature class and the relevant ambient temperature.

3. The causes of malfunction and possible fire/explosion

As written above, the maintenance is of fundamental importance for the correct equipment functionality but also to avoid an explosion.

If we analyse some of the possible causes of malfunction, we can understand how the non-cleaning of electrical and instrumental equipment can affect. In fact, the accumulation of dust on such equipment causes an insufficient or a total lack of thermal transmission, leaving the equipment in the condition of thermal insulation.

The devices, therefore, reach a state of overheating and incorrect operation. As a consequence of this, the air inside will tend to increase, raising the surface temperature which, by exceeding the expected limit of the maximum surface temperature, could cause a fire or an explosion based on the type and the concentration of gas present.

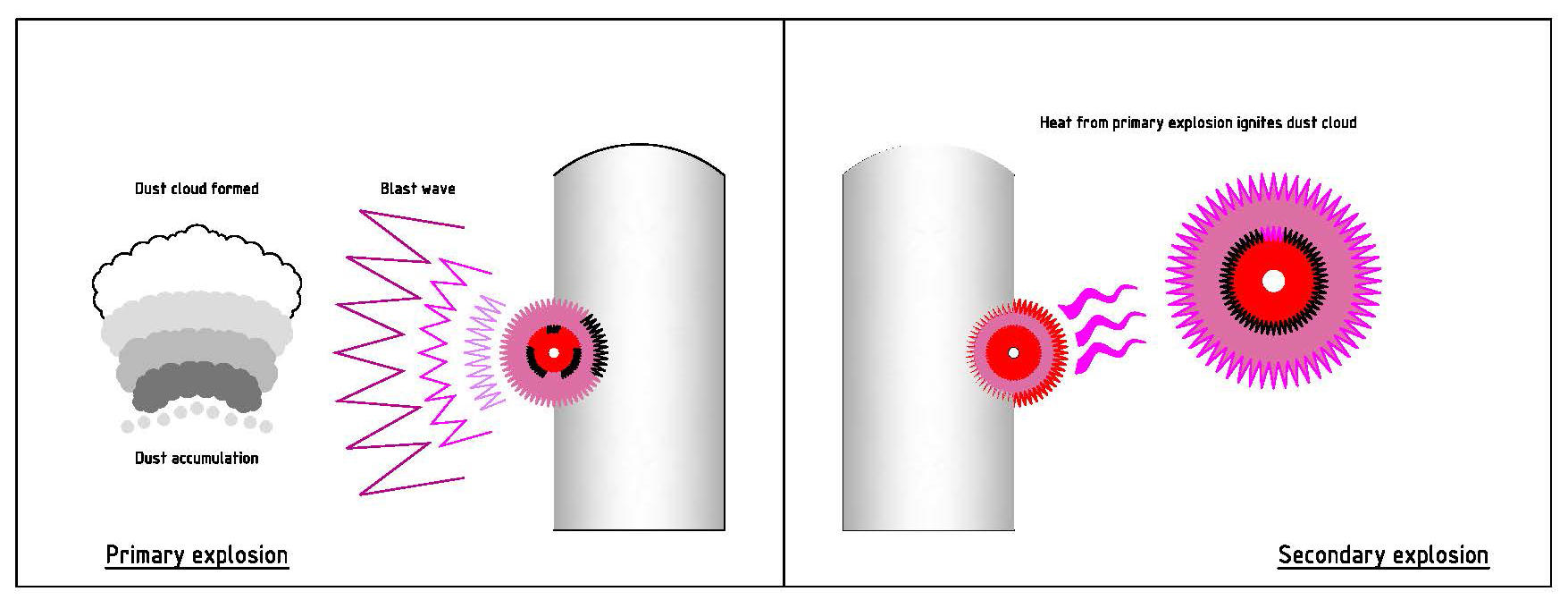

An initial (primary) explosion (Figure 2) in processing equipment or in areas where latent dust has accumulated may dislodge additional dust or damage a collection system (such as a duct, vessel or collector). This dust, if ignited, causes additional explosions (secondary explosion) which can cause damages more severe than the original explosion due to increased concentrations and quantities of dispersed combustible dust.

4. Types of combustible dusts

Dust explosions can occur in any activity in which solid materials are treated and finely divided (metals, organic substances, polymers, resins, coals, wood, etc.). Dust may be the end product of a process or an unwanted by-product. Even very common substances such as wheat flour, cocoa powder, icing sugar, tea, coffee, present an explosion hazard, often masked by their familiar appearance, when they are treated, in powder form, on industrial scale in milling, transport, separation, drying processes.

A myriad of small-sized particles is produced during the processes, thus creating dust. The particles with dimensions that are too large to remain suspended in the air are deposited, while the smaller ones remain suspended for an unlimited period.

5. The construction characteristics

The electrical and instrumental systems suitable for installation in environments with danger of explosion mainly comply with the international, EU and national regulations that are included in the 60079 series.

These systems are divided into zones such as Zone 1 and 2, with the presence of Gas, and Zone 21 and 22 with the presence of dust.

6. The reference Standards for electrical and instrumental equipment installed in presence of dusts

The reference standards for electrical and instrumental equipment installed in the presence of dust are:

- 60079-10-2: standard that determines the criteria for classifying hazardous areas in the presence of potentially explosive dusts.

- 60079-14: standard that dictates the criteria for the design, selection and installation of electrical systems in explosive atmospheres.

- 60079-0: standard that dictates the general prescriptions of equipment addressed to explosive atmospheres.

- 60079-31: standard that determines the requirements for electrical equipment protected by the enclosure and by limiting the surface temperature for use in explosive dust atmospheres. It specifies the requirements for the design, construction and testing of Ex "t" electrical equipment. This regulation does not apply to the explosive dusts which do not require atmospheric oxygen for combustion or pyrophoric substances.

- 60079-32-1: guide on the equipment, the product and the process properties necessary to avoid the ignition and electrostatic shocks deriving from static electricity, as well as the operational requirements necessary to ensure the safe use of the equipment, product or of the process. It can be used in an assessment of the risk of electrostatic hazards or for the preparation of product families or dedicated product standards for machines or electrical or non-electrical equipment.

- 60079-32-2: standard that describes the test methods for the equipment, the product and the process properties necessary to avoid ignition and electrostatic shocks deriving from static electricity. It is intended for use in assessing the risk of electrostatic charges or for preparing product families or dedicated product for electrical or non-electrical machines or equipment.