The combined Ex methods of protection

Combined protection methods represent a fundamental approach to guarantee the safety of electrical equipment in areas classified for the presence of potentially explosive atmospheres. Their application makes it possible to satisfy different construction and operational needs, combining the advantages of the various protection methods available.

by Andrea Battauz, R&D Manager of Cortem Group

Premise

Since the first attempts to make devices used in mines safe, the safety of electrical equipment in areas classified for the presence of potentially explosive atmospheres has made use of different methods of protection depending on the application. For example, electric motors were made with explosion-proof enclosures, while alarm and communication systems used low voltages, subsequently developing the concept of intrinsically safe protection.

The insufficiency of a single method of protection

It is clear that different devices cannot be made with the same type of protection.

For example, the 'Ex e' increased safety method of protection is only applicable to non-sparking equipment or components.

Similarly, the 'Ex m' method of protection, since the electrical component is immersed in a solid resin jet, is not suitable for use for equipment with moving parts such as a free-to-rotate shaft.

And so for many other situations, so much so that even within a single piece of equipment it may be necessary to adopt different protection philosophies for the elements that compose it.

Combined EX protection methods have therefore been developed [1] which involve the application of two or more protection modes to different parts of the same equipment.

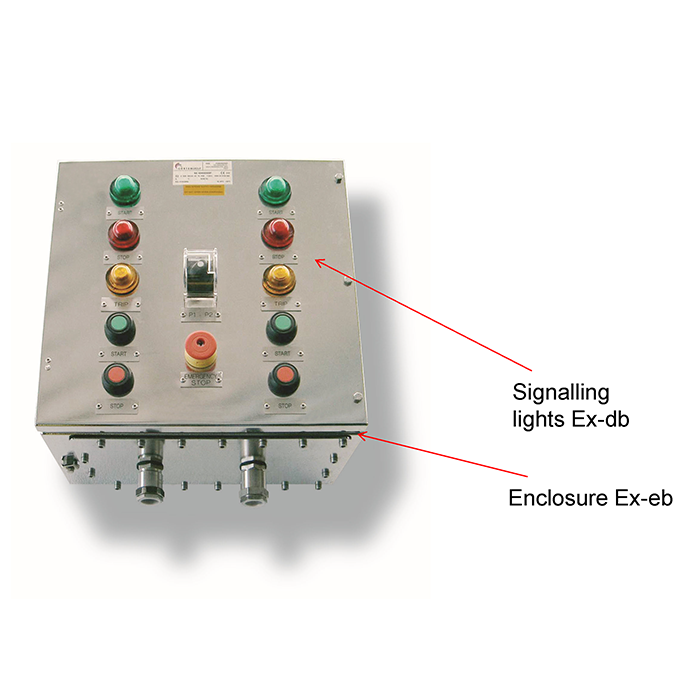

A typical application of combined protection modes are the increased safety panels, an example of which we find in Figure 1.

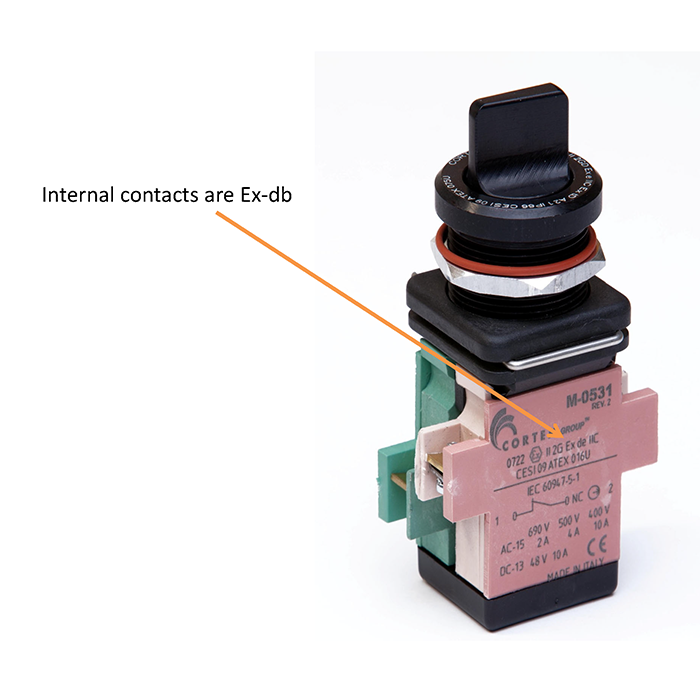

All the components on the panel, such as lights, buttons and selectors, being sparkling, must use a protection method different from the 'Ex eb' one. In this case, internal indicators and contacts are protected using the 'Ex db' explosion-proof protection method. A detail of this can be appreciated in Figure 2 where the marking highlights that an explosion chamber housing the contacts is located inside the selector.

The marking in combined Ex protection methods and of associated equipment

The Standard defines "mode" or "combined protection level" as that of equipment that contains components that use different protection methods. Such a device must show in the marking, or on the plate, the symbols of the protection modes in alphabetical order separated by small spaces. [1]

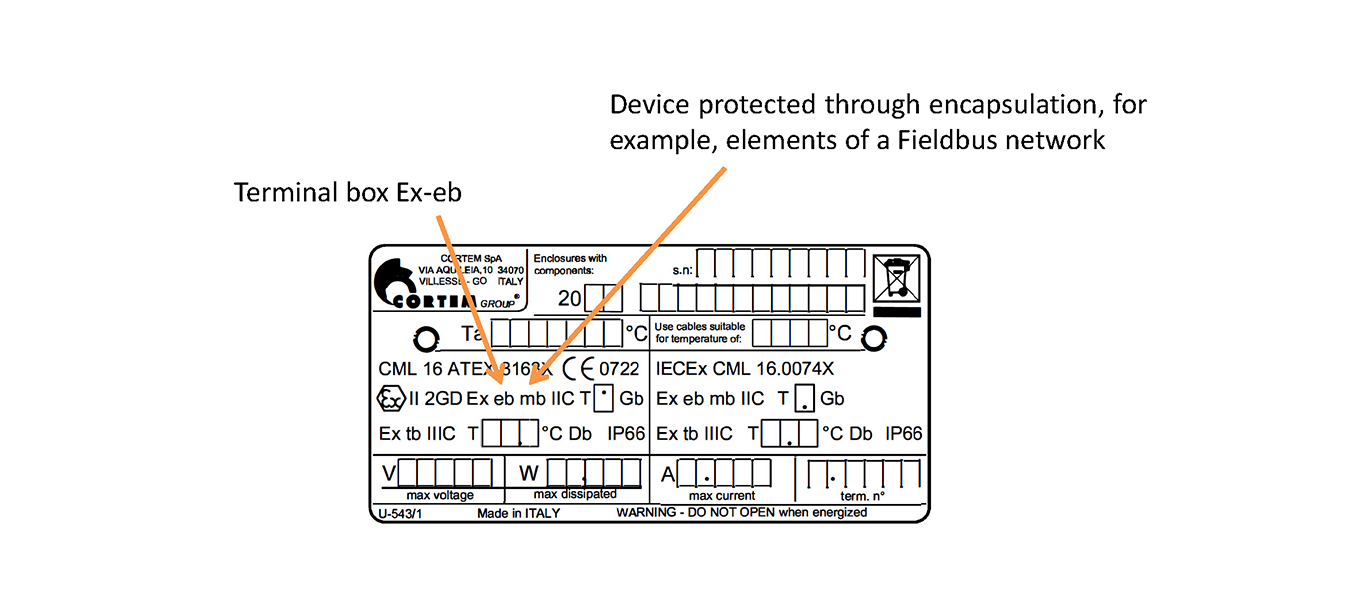

In Figure 3 we see an application case: the increased safety Ex enclosures are used to install devices in the field that are suitable for the installation zone (for example an ' Ex ec' device in Zone 2 or an ' Ex mb' in Zone 1) providing an IP protection degree to the assembly thus created.

The internal protection methods can be different and, on the plate, following the requirements of EN/IEC 60079/0 [1] standard, they are listed in alphabetical order.

Conclusions

In summary, combined protection methods represent a fundamental approach to guarantee the safety of electrical equipment in areas classified for the presence of potentially explosive atmospheres. Their application makes it possible to satisfy different construction and operational needs, combining the advantages of the various protection methods available.

The correct marking and certification of these devices is essential to ensure that each component functions safely and effectively, preventing explosion risks and ensuring operational continuity in dangerous areas.

The continuous evolution of regulations and protection technologies allows us to face increasingly complex challenges, maintaining high safety standards.

Reference standards and bibliography

[1] EN-60079:2013 par. 29.6